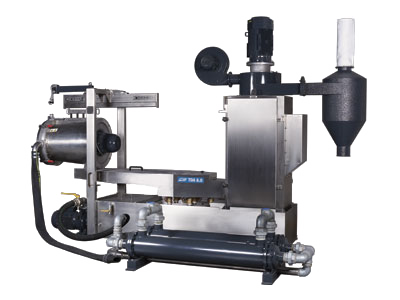

Water ring pelletizer TDA

The pelletizer system completes the recycling process: this is the final part of the plant. The recycled material comes out of the die plate in form of “spaghetti” and it is “cut” by a series of rotating blades into small cylinders which are cooled with water and then dried in a centrifuge. During this stage, the material takes on the form of a granule.

TDA pelletizer characteristics:

The water ring pelletizer TDA allows a fast start/stop sequence and rapid material change. It can be installed on lines suitable to most plastic materials (PE, PP, PS, ABS, MASTER,COMPOUDING etc).

It is also compatible with all the extruder models currently proposed on the market, regardless of the manufacturer.

The Water Ring Pelletizer TDA is available in these sizes: 2.0, 3.4, 4.0, 5.0, 6.0.

- TYPE

- TDA 2.0

- TDA 3.4

- TDA 4.0

- TDA 5.0

- TDA 6.0

- CAPACITY UP TO a Kg/h*

- 170

- 350

- 700

- 1200

- 2200

*The maximum capacity refers to the PE.

Tel +39 0522 240811

Reg.Imp., P.iva e CF: 00486090350

Numero REA: RE - 134846

Capitale sociale (i.v.): € 530.000,00