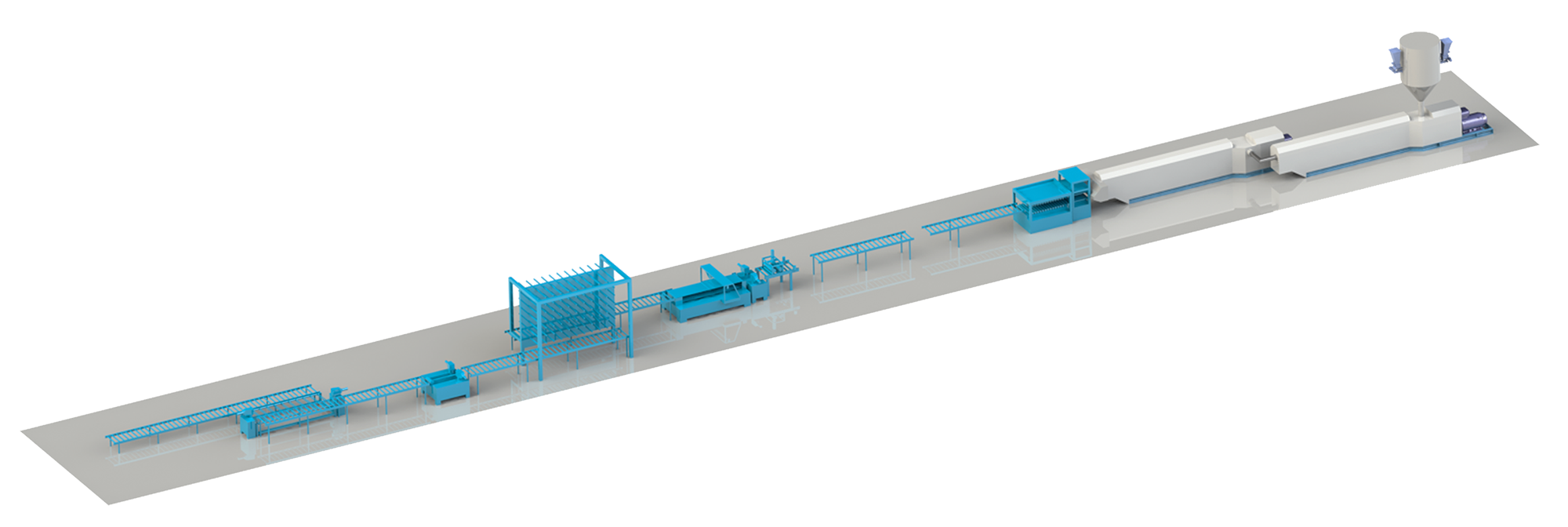

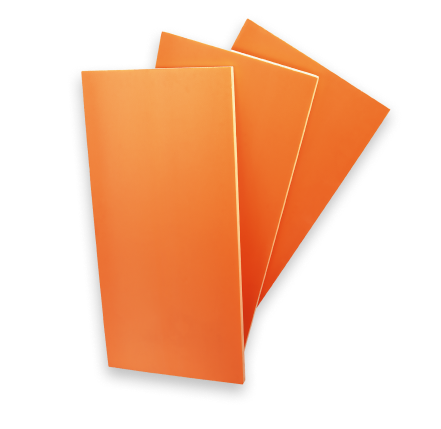

Lines for the production of XPS boards

The capacity of the line for the production of extruded polystyrene XPS boards can vary from 300 to 1500 kg/h, equivalent to 70000-300000 m³ / year.

The production cycle goes through the following steps:

- raw material dosing and feeding

- raw material melting

- expanding gas injection

- foam cooling

- boards forming

- boards cooling

- lengthwise cutting

- side trimming

- pack formation

- packaging with polyethylene film

Watch the video

Via Sacco e Vanzetti, 13 - 42021 Bibbiano (RE)

Tel +39 0522 240811

Reg.Imp., P.iva e CF: 00486090350

Numero REA: RE - 134846

Capitale sociale (i.v.): € 530.000,00

Tel +39 0522 240811

Reg.Imp., P.iva e CF: 00486090350

Numero REA: RE - 134846

Capitale sociale (i.v.): € 530.000,00