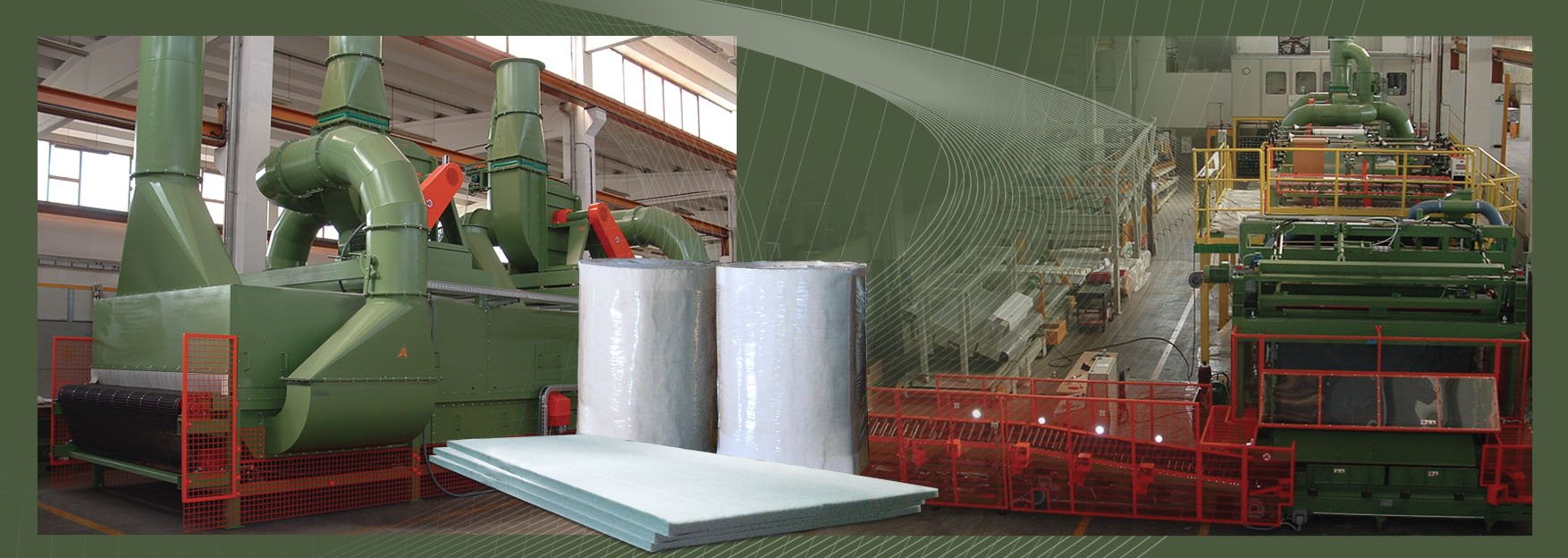

Ceramic Fiber production lines

A complete ceramic fiber production line consists of several machines from storage of the raw materials to the packaging of the final product.

The working width of a production line is usually from 1220 mm (48 “) to 2440 mm (96”).

Ceramic fiber production steps

The first step of ceramic fiber production process (hot area) consists of storage, dosage, mixing and fusion of raw materials, then follows the fiberizing.

The parts of machinery composing this section of the line generally are:

- storage, mixing and feeding equipment for raw materials (silos, scales, conveyors, hoists etc);

- melter (electric furnace);

- fiber forming unit (fiberizing machine, collecting chamber and auxiliary plant).

The second step of the production process consists of the felt treatment.

The machines dedicated to this function are:

- collecting system for the flakes of bulk fiber;

- needling machine;

- annealing oven;

- cooling conveyor;

- group of edge trimming and longitudinal cut (cut and edge trimming in width, longitudinal cut at measure, milling and sending of the milled material to the collecting chamber for a complete reuse);

- chopper for cut at the required length.

The third step of the production process includes the packaging operations and storage. The operating machines are:

- automatic roll up and wrapping of the rolls with plastic film or paper;

- thermoshrinking of the plastic film on the ends of the rolls;

- insertion of the rolls in carton boxes and/or on pallet;

- packaging and sealing of the pallets;

Every section for the ceramic fiber production is designed as per the specific requests of customer.

This allows the development of a customer-supplier rapport based on trust and collaboration, which continues for the entire lifetime of the system thanks to the Gamma Meccanica post-sales service.

Types and characteristics of the ceramic fiber products

- Needle felts;

- Rigid boards;

- Bagged or boxed bulk flakes;

Characteristics of the products:

- Density max 160 Kg/m3

- Thickness min 10 mm

- Width of final products 610 – 1220 mm

Would you like to know more?

Contact us for a consultation