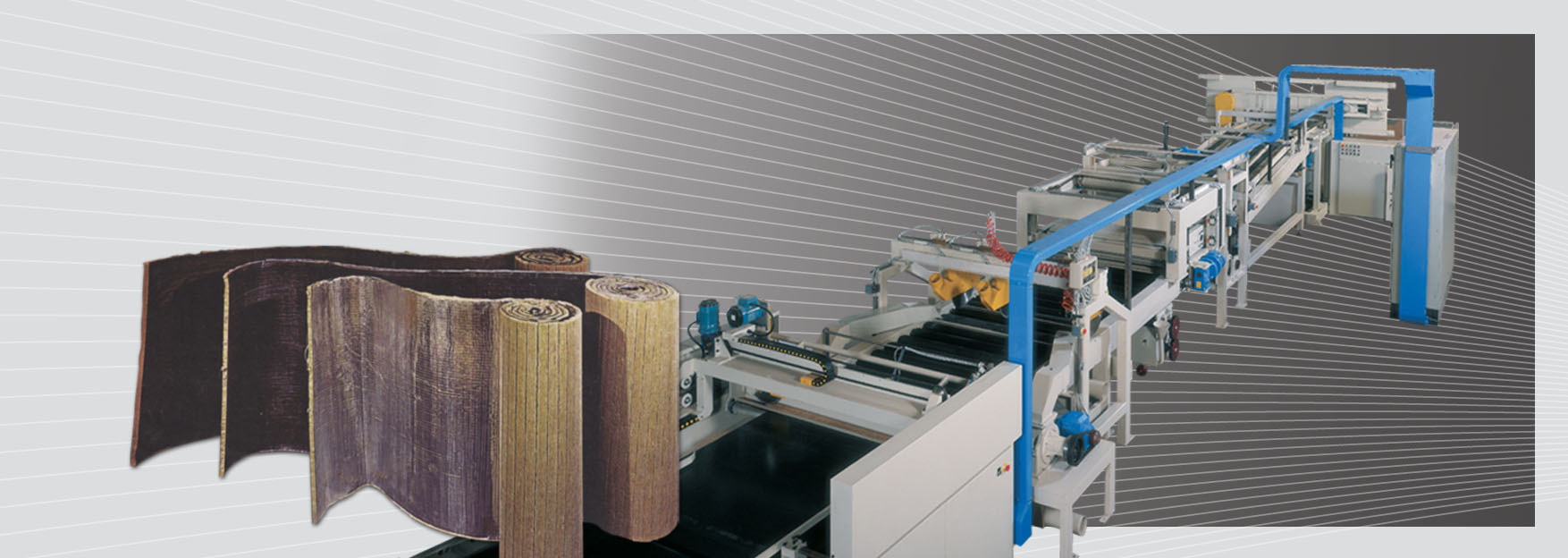

Lamella mat production lines

Lamella mat production lines

The lamella mat production lines produce mats with vertically “oriented” fibers: these products have high compressive strength, though have relatively low density.

Starting from stacks of glass wool or rock wool boards it is possible to obtain strips of material (lamellas) which are then rotated till the fibers become vertically oriented and then aligned.

In the next part of the process a continuous mat is coupled with facing material (aluminium, glass tissue, bituminous casing).

The mat is trimmed and cut at required width and length, then it’s rolled up or stacked and packed.

The lamella mat production line guarantees a high efficiency and it is completely automatic.

Characteristics of lamella mat production line

The main characteristics of lamella mat production lines:

- automatic de-stacking and cut of the boards to obtain lammellas

- automatic orientation of the fibers

- high precision coupling of lamella mat with various types of facing material and bonding.

- low quantity of manpower and complete automation of each production step.

Would you like to know more?

Contact us for a consultation