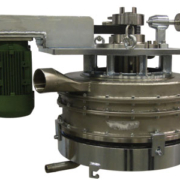

Fiberizer, spinning machine for glass wool production lines

The fiberizer is installed under the feeder.

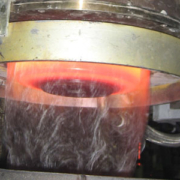

The melted glass, opportunely dosed through special openings (bushing), electroheated and cooled, arrives to the fiberizers that essentially consist of perforated disc that rotates at high speed and is thermoheated.

Due to the centrifuge force, the glass is pushed through the perforated disc openings (using compressed air and combustion gas of special burners at high pressure) and is trasformed into fiber.

The fiberizing parameters (burner temperature, flame pressure, ratio air/ gas, flow speed of air and gas) are managed by the control system to determine the fiber diameter and the length on the basis of needs.

Usually, to achieve the requested capacity of the line, several fiberizers are used in parallel.

The dimensions and capacity of each fiberizer depend of perforated disc diameter. The capacity can vary from 300 to 950 kg/h of fiber for each single machine.