Edges and surfaces finishing for extruded polystyrene (XPS) boards

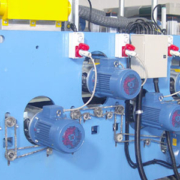

The edges and surfaces finishing takes place once the XPS boards are cooled.

The finishing is required to remove the excess material, then follows the cutting operation to obtain single boards.

The cutting unit defines the length of the boards.

The edges finishing unit has to finish the board processing in longitudinal and transversal direction.

The profile can vary according to customer’s request.

The surfaces of the extruded polystyrene board can be further processed, removing the superficial skin or processing it with an appropriate embossing system, by creating grooves for different purposes.

The finished board is stacked and packed with shrinking film.

Photogallery

Discover the other machines

Would you like to know more?

Contact us for an expert advice