Extrusion group for extruded polystyrene production lines

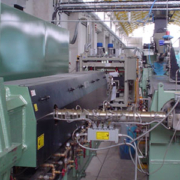

The extrusion group for extruded polystyrene (XPS) boards is the first phase of the production process and it is used to melt, mix and cool the raw materials. The mixture of raw materials is aspirated and loaded in the dosing system and sent to the extrusion group.

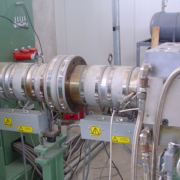

The standard configuration includes two extruders placed in tandem: a primary extruder may be single screw or twin screw type, and a secondary one is always single screw.

The primary extruder melts the raw material injecting blowing agent into the molten material and feeds the secondary extruder.

The secondary extruder is used to make a further mixing, to cool the material, to correct the expansion temperature and to send the material to the die head.

The foam that comes from the extrusion group passes through the die head and the calibrator and is transformed into the board.

Photogallery

Discover the other machines

Would you like to know more?

Contact us for an expert advice